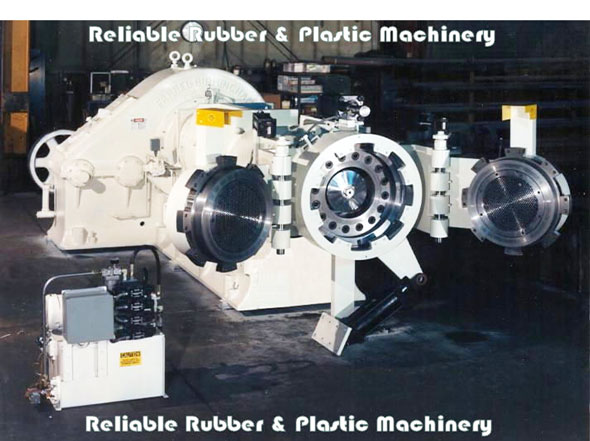

Rubber Extruders/Strainers

RELIABLE'S comprehensive rubber extruder/strainer, hot feed and cold feed, rebuilding capabilities are industry renown. Our forte is providing cost effective solutions to match your exact process applications. Based on your process requirements, the rebuilding procedure includes relining the barrel, incorporating new screw designs and integrating & upgrading the controls and drive system, while ensuring all new tolerances. We will manufacture head designs to meet your process requirements.

At RELIABLE, we engineer each rubber extruder/strainer to your exact requirements.

Rubber Extruders/Strainers

| Stock | Description | |

|---|---|---|

| 1 | "Farrel" 15" w/Pneumatic Stuffer | |

| 2 | "Farrel" 15"x12" w/Pneumatic Stuffer | |

| 2 | “Davis Standard” 3 1/2” Extruders w/Power Roller Feed | |

| 1 | "Royle" 10" Hot Feed | |

| 1 | "NRM" 8" Hot Feed Strainer | |

| 3 | "NRM" 6" Hot Feed | |

| 2 | "Royle" 6" Hot Feed | |

| 1 | "NRM" 4 1/2" Cold Feed w/Power Roller Feed - 125 HP | |

| 1 | “NRM” 4 1/2” Cold Feed 17:1 L/D w/Power Roller Feed - EXCELLENT CONDITION | |

| 1 | “NRM” 3 1/2” Cold Feed w/Power Roller Feed | |

| 1 | “NRM” 1 1/2” Cold Feed | |

| 1 | “Maag” 2 1/2” Pin Barrel Extruder with Gear Pump EXCELLENT CONDITION | |

| 1 | “Royle” 2” Hot Feed | |

| 1 | “Barwell” Model “Midi” Preformer - ram type |